Printing Jargon Explained

There is a lot of information to sift through when it comes to print terminology and design jargon. This article will help break down print jargon terms or phrases that can leave one a little confused.

Artwork or A/W

Normally, a design agreed between a creative designer and the client is purely a visual representation.

An artwork file is the method which a designer creates a different file than the one proofed by the customer. This file is in a format needed by the printing company, in order to be able to process the design and make it print.

Binding

The method used to hold several sheets of paper or board together within a booklet or brochure.

Collating

When several sheets are printed in order to make up a document, the sheets can be printed independently or all together. After they are printed, they need to be gathered together in the correct order before they are bound.

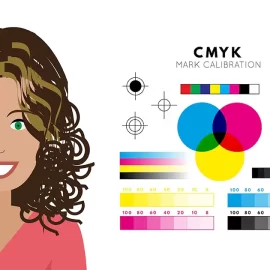

Colour separation

The computerised process which creates the four-colour or full-colour separation of design and artwork, so it can be printed using the CMYK process.

Embossing

An image – usually a logo – is pressed into the paper so it dents just below the surface, like a depression in the paper. The same technique is used for debossing.

Grain

During the paper-making process, all the pulp fibres run lengthwise, which doesn’t create stability. In order to create a web of fibres, pulp is shaken from side to side, forcing some of the fibres into a horizontal position and creating a crisscross. The majority of the fibres still run with the flow, giving you the grain direction of your paper.

Folding

Folding is probably the most important reason why you need to know the direction of your grain direction.

Folding with the grain is smoother, even in heavier sheets, and you only need to consider scoring when using heavier cover weights. When folding against the grain, though, you always need to score. Scoring prepares the paper for folding and greatly reduces cracking on the fold.

Resolution

Refers to the degree of detail of an image. It is usually measured in dots per inch (dpi) or lines per inch (lpi). A high resolution gives a high-quality image and vice versa.

Shrink wrrapping

Method of packing printed products etc, by surrounding them with plastic, then shrinking by heat. Shrink wrap can actually be very beneficial for maintaining your product.

Substrate

A substrate is the material you choose to print on. Therefore, a substrate can be a variety of materials, including – but not limited to: paper, plastic, wood, glass, rubber and cloth. There are endless possibilities.

Varnishes

Special varnishes can be applied to printed matter to protect from ink smudging or finger marking or to enhance appearance.

There are 5 main types – machine, gloss, matt and silk and UV. Varnishes are commonly used on matte or silk coated paper, as these types are more prone to smudging than gloss coated paper.

Varnish applied to specific area of a document is known as spot varnish and when it’s applied to the whole document, it is termed as an overall varnish.

SOURCE: Imagine